Hot LIne

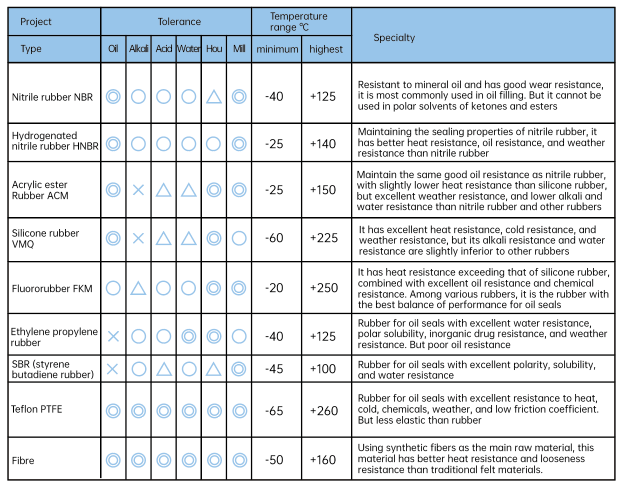

Note (1): For oil resistance, it does not contain flame retardant oils such as phosphate ester series and water ethylene glycol series

Note (2): The temperature ranges in the table are applicable to the following standards

High temperature aspect

After conducting a 70 hour air heating aging test, the tensile strength change rate is ± 30%, the elongation change rate is -50%, and the hardness change is within ± 15 degrees, suitable for the highest temperature. [The maximum temperature here applies to the heat resistance period standard temperature for material evaluation specified by ASTM D2000 Line Callouts.]

Low temperature aspect

Applicable TR10 value

TR stands for Temperature Retrieval. Indicating the recoverability of deformation in the low-temperature field as specified by ATSM D 1329. The degree of elastic recovery is roughly the same as that of rubber elastomers. The TR value is the temperature at which the sub deformation recovers by 10%.